Jeff Coombe

The Ethanol industry has only responded tepidly to the Volumetric Ethanol Excise Tax Credit in the past, so why should it be renewed?

The U.S. ethanol industry is nearing a major deadline. The industry's primary subsidy mechanism, the Volumetric Ethanol Excise Tax Credit (VEETC), is set to expire on December 31, 2010.

Federal ethanol subsidies were worth roughly $5 billion in 2009, a figure large enough to create vigorous debate over their renewal. Some call the credits a boondoggle, others a vitally important lifeline for an industry still in its formative years.

Whichever it is, one has to wonder whether we as a country and as taxpayers are getting our money's worth for it. All subsidies are intrinsically positive for the industries they support, of course. But how much of an impact is really felt by the industry, especially as compared to the cost to the taxpayer, is much harder to quantify.

This article will look at the history of subsidies and other government support mechanisms for the ethanol industry, and how they result in increased production, plant construction, and stock pricing. By lining up the dates of landmark legislation with several industry performance metrics, we are able to view the industry response in terms of production and growth, rather than rhetoric. Only pure-play ethanol company stocks are reviewed, represented here by

Andersons, Inc. (ANDE),

Pacific Ethanol (PEIX),

BioFuel Energy Corp. (BIOF), and the now-defunct

VeraSun Energy (VSE).

The data below is a limited snapshot, and cannot account for the myriad of variables that affect the ethanol industry. Supply-and-demand market conditions, economic climate, and even public perception impact businesses and investment decisions. While keeping this in mind, it is still striking how little of an effect the VEETC, by far the largest biofuel subsidy, has on the industry as a whole. Almost no metrics responded positively to key dates in the VEETC history, instead seeming to respond much more to direct producer incentives and production / use mandates.

History of Ethanol Incentives

The VEETC was enacted on October 22, 2004 with the American Jobs Creation Act, and set a $0.51/gallon credit for any blender of ethanol into the petroleum gasoline stream. It replaced a convoluted set of subsidies begun in 1979, with a partial federal tax exemption of gasoline blended with at least 10% ethanol (gasohol) by the Energy Tax Act. Fuel blender's tax credits and a pure alcohol tax credit were subsequently added, achieving roughly the same goals, but available to smaller fuel blenders that were unable to receive the excise tax exemption. The VEETC streamlined this system and provided a single mechanism for subsidizing ethanol use. The 2008 Farm Bill reduced the VEETC credit to $0.45/gallon.

One other federal tax credit applied to ethanol, the Small Ethanol Producer Tax Credit. Enacted in 1990, this credit allowed plants producing less than 30 million gallon per year to receive a $0.10/gallon credit for the first 15 million gallons of fuel produced annually. The size of plants that can receive the tax credit was subsequently raised to 60 million gallons per year, though it still only applied to the first 15 million gallons of annual production. The Small Ethanol Producer Tax Credit also expires at the end of 2010. In addition, some 30 states have enacted their own biofuel incentive measures.

The federal government also uses non-monetary support mechanisms to assist the ethanol industry. Foremost amongst those is the Renewable Fuel Standard (RFS), enacted with the August 8, 2005 Energy Policy Act, and amended with the Energy Independence and Security Act, signed into law on December 19, 2007. RFS1 was the 2005 version, and mandated that specific minimum volumes of ethanol be blended with gasoline in the national fuel pool. Starting at 4 billion gallons in 2006, the RFS ramped up the minimum volume of ethanol that had to be blended with gasoline to 7.5 billion gallons by 2012. The industry grew much faster than expected, though, and in 2007 the RFS was amended (RFS2). This raised the minimum volume of corn ethanol blending to 15 billion gallons per year, and adds another 20 billion gallons of cellulosic ethanol, biodiesel, and other advanced renewable fuels by 2022.

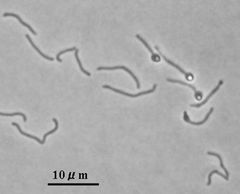

Early Years of the Ethanol Industry

Ethanol production as a large-scale industry began in the 1970's. Over 150 ethanol plants, mostly small on-farm distilleries, were built in response to the OPEC oil crisis and fuel prices spikes. However, many plants were going out of business by the end of the decade, and the first ethanol subsidy was installed in 1979 to support the flagging industry. While the volume of production steadily rose in the 1980's and 1990's, the excise taxes failed to stem the drop in plant numbers. By the mid-1980's, there were less than 40 ethanol plants in the U.S. Figure 1 shows numbers of U.S. ethanol plants and production numbers from 1960-2000. Reliable ethanol production volumes were not tracked until 1980.

*Source: RFA 2010 Ethanol Industry Outlook

**Source: BBI International

*Source: RFA 2010 Ethanol Industry Outlook

**Source: BBI International

While the total number of plants barely changed in the 1980's and early 1990's, larger scale plants were being constructed and the ethanol production volume increased steadily over that time period. The Small Ethanol Producer Tax Credit was installed in 1990, and likely contributed to an increase in total production from 900 million gallons in 1990 to 1.4 billion gallons in 1995. How this credit was set up is in itself an indicator of its impact on the ethanol industry. The Small Ethanol Producer Tax Credit is the only credit that is paid directly to the companies that make ethanol. The VEETC and its predecessor excise credits are paid to fuel blenders, which are often petroleum refineries or bulk distributors, and not the ethanol producers themselves. While the majority of the excise credit finds its way back to producers in the form of better prices for their product, the subsidy effectively incentivizes oil companies to use ethanol.

Boom Times

Everyone knows the ethanol industry experienced a boom cycle in the mid-2000's. What is less agreed upon is what set of market forces really caused this boom. Contrary to popular belief, the data shows that the VEETC, enacted in 2004, did not immediately result in a change of ethanol plant construction. Between 2002 and 2005, the number of new plants or plant expansions announced held relatively static in the neighborhood of 15 plants per year. Total production capacity of plants grew slightly during that time. The real growth in the ethanol industry came in 2006 and 2007, which more closely corresponds to the RFS implementation. Figure 2 shows the relative inactivity between 2004 and 2005, and the large increase in construction projects from 2006-2008.

It is important to take into account the lag time between when a project is conceived and construction begins. This lag allows for the requisite capital to be raised, construction firms contracted, and other aspects of the project to be developed to the point that construction can be announced. In the ethanol industry, and especially in the boom years, the project development period is usually on the order of 12-18 months. If the VEETC was a major difference maker in the decision to build an ethanol plant, at least some early adopters would have been able to capitalize in 2005, and would have registered an uptick in construction. As it worked out, though, the bulk of industry growth came 2-3 years later.

Source: Renewable Fuels Association

Source: Renewable Fuels Association

A measure of a company's health, and the most immediate indicator of positive and negative changes affecting a company, are shown in its stock price. In today's investing world, stock prices respond instantly to the slightest news, and it is here that the indifference towards the VEETC is most apparent.

If financial experts had agreed it was vital for the industry, stock prices should have jumped after signing of the VEETC. On the contrary, Figure 3 shows that there was almost no change in ethanol company stock pricing in 2004 and most of 2005. It was late-2005 and 2006 before the pure-play ethanol company stocks began their meteoric rise, immediately after signing of RFS1. Later, the increase in mandated volumes of ethanol production, through RFS2 in 2007, lines up with minor spikes in all four stock prices. This data indicates that investors were more responsive to RFS legislation than the VEETC. (Stocks are shown as a percentage of their highest point within the time period, in order to show the wide range of share values on one graph.)

The other end of the boom (late 2008 and 2009) saw the bankruptcy of VeraSun, sharp drops in ethanol stocks and almost instant halting of all ethanol plant building, including some projects in mid-construction. All of this occurred while the VEETC was in the middle of its 6-year effective term, and the RFS was being increased to its 36 billion gallon goal.

The reduction of the VEETC in 2008 does correspond with reductions in the numbers of plants constructed and stock values. A change of $0.06/gallon in the credit reduces profit to a 100 million gallon plant by $6 million annually, so this change was definitely felt by producers. By that time, however, corn feedstock prices had hit an all-time high, oil prices had crashed, and a recession was hitting the U.S. economy. These forces impacted the industry much more than changes to the federal incentives packages could help. On the other hand, the fact that the industry is still alive today is probably due in part to those support mechanisms.

Going Forward

Does this show that ethanol companies and the investors who fund plant construction were more interested in the guaranteed market for their product resulting from the RFS, rather than increases in profit from the tax credit? Or are subsidies, while easy to point to, insignificant in the face of the much larger economic forces that really determine the health of the industry (general economic and investment climate, crush spread, etc)?

It is impossible to argue that the VEETC did not help spur investment into the ethanol area, and equally as difficult to argue that it isn't helping the industry through the bad times. It is not a perfect incentive, however. The purpose of the VEETC was to equalize the cost of ethanol with gasoline, but at times it has not been enough to help the producers, and at other times bonus profit on top of an already profitable product. Creating a guaranteed market for ethanol through mandated volumes of use, via RFS1 and RFS2, seems have a much greater effect on the industry at a much lower cost. Mandated use stabilizes the market, and still allows for the most efficient, low-cost producers to rise to the top.

A bill for renewing the VEETC and Small Ethanol Producer Tax Credit has been proposed in the House and Senate. Cattle and dairy groups have raised opposition to the measure, not interested in supporting their competition for corn any longer. Many groups feel the ethanol industry, at least the corn-based subset of the industry, has matured and should not need further subsidization in the form of tax credits.

With the biofuels industry mired in a worse rut than the overall U.S. economy, government efforts to help the industry should not be cut. However, alternative incentive schemes need to be devised that provide more bang for the taxpayer buck. Systems including grants and loan guarantees for the construction of plants using second-generation feedstocks,

a blending equalization scheme recently proposed in Biofuels Digest, and

a new tax-and-tariff system proposed by researchers at Iowa State University and the USDA are all being discussed. With the current subsidy set to expire, now is the best time to explore better and more effective support schemes for the U.S. biofuels industry.

Jeff Coombe has been in the renewable energy and environmental science field for 7 years, including experience developing ethanol and biodiesel production facilities, project management for end use vehicle fleet conversions to alternative fuels, and environmental protection management. He is an active member of the Colorado Governor’s Biofuels Coalition steering committee, and has presented research findings at conferences including the International Algae Congress (Amsterdam, Netherlands), the Advanced Biofuels Workshop (Portland, Oregon), and the Colorado Renewable Energy Conference (Pueblo, Colorado). Strengths include data acquisition and analysis, emerging feedstock and production technologies, and inter-industry relations. Mr. Coombe is currently seeking a project development position with a company local to the Denver, CO area.

Click here to view his resume and biography.